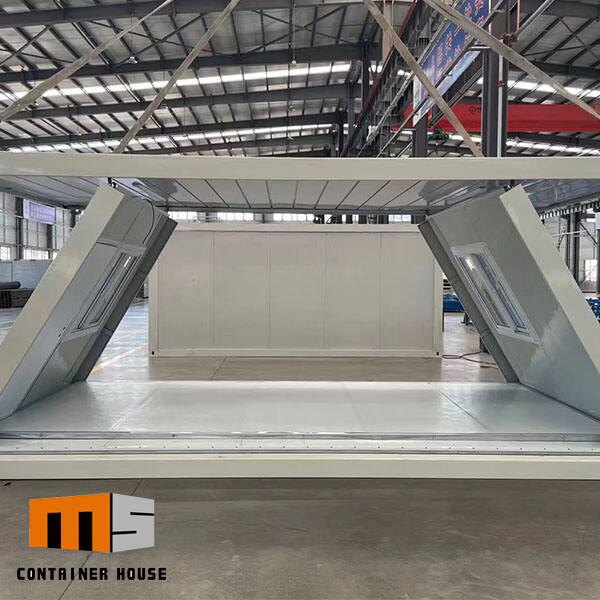

modular house factory

A modular house factory represents the cutting-edge intersection of manufacturing efficiency and modern construction technology. These facilities operate as sophisticated production centers where individual housing modules are manufactured under controlled conditions using advanced automation and precision engineering. The factory setting enables streamlined assembly line processes, incorporating state-of-the-art machinery and quality control systems to ensure consistent production standards. Each module undergoes careful fabrication, from structural components to interior finishes, with integrated electrical, plumbing, and HVAC systems installed on the factory floor. The facility utilizes computer-aided design and manufacturing systems to maintain precise specifications and minimize waste. Quality assurance checkpoints throughout the production process guarantee that each module meets strict building codes and safety standards. Advanced material handling systems and climate-controlled environments ensure optimal construction conditions regardless of external weather conditions. The factory setting also allows for concurrent module production, significantly reducing overall construction timelines compared to traditional building methods. Modern modular house factories typically feature multiple production lines, material storage areas, and specialized stations for different construction phases, from framing to finishing.